The world of belt technology and supply solutions is a vast and fascinating one, filled with innovations that are revolutionizing industries and transforming the way we live and work. From advanced materials and manufacturing techniques to cutting-edge design and functionality, the latest developments in belt tech are having a profound impact on everything from heavy industry and transportation to sports and fashion.

At the heart of this revolution are five essential belt tech and supply solutions that are driving progress and pushing the boundaries of what is possible. These solutions are not only improving efficiency, reducing costs, and enhancing performance, but also opening up new opportunities for growth, innovation, and sustainability.

1. Customizable Belt Solutions

One of the most significant advances in belt tech is the ability to customize belts to meet specific needs and applications. Whether it's a specialized belt for a particular industry, a custom-designed belt for a unique application, or a tailored solution for a specific customer, customizable belt solutions are providing unparalleled flexibility and versatility.

With the use of advanced materials, manufacturing techniques, and design software, belt manufacturers can now create customized belts that meet exacting specifications and requirements. This has opened up new opportunities for industries such as aerospace, automotive, and healthcare, where customized belts can be designed to meet specific performance, safety, and regulatory requirements.

Benefits of Customizable Belt Solutions

- Improved performance and efficiency

- Enhanced safety and reliability

- Increased flexibility and versatility

- Ability to meet specific industry or application requirements

- Reduced costs and improved ROI

2. High-Performance Belt Materials

The development of high-performance belt materials is another key area of innovation in belt tech. These advanced materials are designed to provide improved strength, durability, and resistance to wear and tear, making them ideal for demanding applications in industries such as manufacturing, mining, and construction.

High-performance belt materials include advanced polymers, elastomers, and composites that are engineered to provide superior performance and reliability. These materials are also often designed to be more sustainable and environmentally friendly, reducing waste and minimizing environmental impact.

Benefits of High-Performance Belt Materials

- Improved strength and durability

- Enhanced resistance to wear and tear

- Increased reliability and reduced maintenance

- Reduced environmental impact and improved sustainability

- Ability to meet demanding application requirements

3. Smart Belt Technologies

The integration of smart technologies into belt design and manufacturing is revolutionizing the way belts are used and interacted with. Smart belt technologies include advanced sensors, monitoring systems, and control algorithms that enable real-time monitoring and control of belt performance.

These technologies are enabling industries such as manufacturing, logistics, and transportation to optimize belt performance, reduce downtime, and improve overall efficiency. Smart belt technologies are also being used to develop more sustainable and environmentally friendly belt solutions.

Benefits of Smart Belt Technologies

- Real-time monitoring and control of belt performance

- Improved efficiency and reduced downtime

- Enhanced safety and reliability

- Ability to optimize belt performance and reduce energy consumption

- Development of more sustainable and environmentally friendly belt solutions

4. Sustainable Belt Solutions

The development of sustainable belt solutions is a critical area of focus in the belt tech industry. With growing concerns about environmental impact and sustainability, belt manufacturers are developing solutions that reduce waste, minimize environmental impact, and promote more environmentally friendly practices.

Sustainable belt solutions include the use of recycled materials, biodegradable materials, and energy-efficient manufacturing processes. These solutions are not only reducing the environmental impact of belt production but also providing cost savings and improved performance.

Benefits of Sustainable Belt Solutions

- Reduced environmental impact and waste

- Improved sustainability and reduced carbon footprint

- Cost savings and improved performance

- Ability to meet regulatory requirements and industry standards

- Enhanced brand reputation and social responsibility

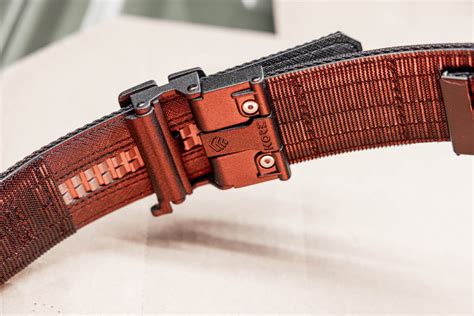

5. Advanced Belt Design and Manufacturing

The use of advanced design and manufacturing techniques is transforming the belt tech industry. With the use of computer-aided design (CAD) software, 3D printing, and advanced materials, belt manufacturers are able to create complex and customized belt designs that meet exacting performance and application requirements.

Advanced belt design and manufacturing techniques are enabling industries such as aerospace, automotive, and healthcare to develop more sophisticated and high-performance belt solutions. These solutions are providing improved efficiency, reduced costs, and enhanced safety and reliability.

Benefits of Advanced Belt Design and Manufacturing

- Improved performance and efficiency

- Enhanced safety and reliability

- Reduced costs and improved ROI

- Ability to meet specific industry or application requirements

- Development of more sophisticated and high-performance belt solutions

What are the benefits of customizable belt solutions?

+Customizable belt solutions provide improved performance, enhanced safety, and increased flexibility. They can be designed to meet specific industry or application requirements, reducing costs and improving ROI.

How do high-performance belt materials improve belt performance?

+High-performance belt materials provide improved strength, durability, and resistance to wear and tear. They can withstand demanding applications and reduce maintenance requirements.

What are the benefits of smart belt technologies?

+Smart belt technologies provide real-time monitoring and control of belt performance, improving efficiency and reducing downtime. They can also optimize belt performance and reduce energy consumption.