The manufacturing industry has undergone significant transformations in recent years, driven by advances in technology, changing market demands, and the need for increased efficiency. One of the key players in this evolution is Bend-Tech, a company that offers innovative software solutions designed to streamline and optimize manufacturing processes.

Bend-Tech's software solutions are tailored to meet the specific needs of modern manufacturing, providing a range of benefits that can help businesses stay competitive in today's fast-paced market. From improving production efficiency to enhancing product quality, Bend-Tech's software is designed to help manufacturers overcome common challenges and achieve their goals.

What is Bend-Tech Software?

Key Features of Bend-Tech Software

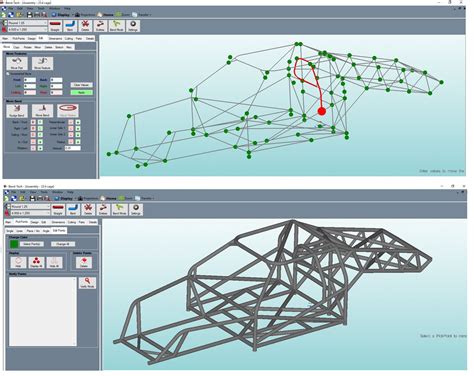

Bend-Tech's software solutions offer a range of features that can help manufacturers streamline their operations, improve efficiency, and enhance product quality. Some of the key features of Bend-Tech software include:- Design and Engineering Tools: Bend-Tech's software includes design and engineering tools that enable manufacturers to create detailed designs and simulations of their products. This can help identify potential issues early in the development process and ensure that products meet specifications.

- Production Planning and Scheduling: Bend-Tech's software includes production planning and scheduling tools that enable manufacturers to optimize their production processes. This can help reduce lead times, improve efficiency, and enhance product quality.

- Quality Control and Inspection: Bend-Tech's software includes quality control and inspection tools that enable manufacturers to monitor and control the quality of their products. This can help identify potential issues early in the production process and ensure that products meet specifications.

- Data Analytics and Reporting: Bend-Tech's software includes data analytics and reporting tools that enable manufacturers to track key performance indicators (KPIs) and make data-driven decisions. This can help manufacturers identify areas for improvement and optimize their operations.

Benefits of Using Bend-Tech Software

- Improved Efficiency: Bend-Tech's software can help manufacturers streamline their operations and improve efficiency. This can help reduce lead times, improve productivity, and enhance product quality.

- Enhanced Product Quality: Bend-Tech's software can help manufacturers monitor and control the quality of their products. This can help identify potential issues early in the production process and ensure that products meet specifications.

- Reduced Costs: Bend-Tech's software can help manufacturers reduce costs by optimizing their production processes and minimizing waste.

- Increased Transparency: Bend-Tech's software can provide manufacturers with real-time visibility into their operations, enabling them to make data-driven decisions and optimize their processes.

Real-World Applications of Bend-Tech Software

Bend-Tech's software solutions have been used in a range of industries, including aerospace, automotive, and industrial equipment manufacturing. Some examples of real-world applications of Bend-Tech software include:- Aerospace Manufacturing: Bend-Tech's software has been used by aerospace manufacturers to design and engineer complex aircraft components. The software has helped manufacturers optimize their production processes and improve product quality.

- Automotive Manufacturing: Bend-Tech's software has been used by automotive manufacturers to design and engineer complex vehicle components. The software has helped manufacturers optimize their production processes and improve product quality.

- Industrial Equipment Manufacturing: Bend-Tech's software has been used by industrial equipment manufacturers to design and engineer complex machinery. The software has helped manufacturers optimize their production processes and improve product quality.

Implementation and Integration of Bend-Tech Software

- Needs Assessment: The first step in implementing Bend-Tech software is to conduct a needs assessment. This involves identifying the specific needs and goals of the manufacturer and determining how the software can help meet those needs.

- Software Configuration: Once the needs assessment is complete, the next step is to configure the software to meet the specific needs of the manufacturer. This may involve customizing the software to integrate with existing systems and processes.

- Training and Support: After the software is configured, the next step is to provide training and support to ensure that users are able to effectively use the software. This may involve on-site training, online support, and documentation.

- Ongoing Maintenance and Support: Finally, Bend-Tech provides ongoing maintenance and support to ensure that the software continues to meet the evolving needs of the manufacturer.

Best Practices for Implementing Bend-Tech Software

To ensure a successful implementation of Bend-Tech software, manufacturers should follow best practices, including:- Clearly Define Goals and Objectives: Manufacturers should clearly define their goals and objectives for implementing Bend-Tech software. This will help ensure that the software is configured to meet their specific needs.

- Provide Adequate Training and Support: Manufacturers should provide adequate training and support to ensure that users are able to effectively use the software.

- Monitor and Evaluate Performance: Manufacturers should monitor and evaluate the performance of the software to ensure that it is meeting their needs and providing the expected benefits.

Conclusion

Bend-Tech's software solutions offer a range of benefits that can help manufacturers streamline their operations, improve efficiency, and enhance product quality. By implementing Bend-Tech software, manufacturers can optimize their production processes, reduce costs, and improve transparency. To ensure a successful implementation, manufacturers should follow best practices, including clearly defining goals and objectives, providing adequate training and support, and monitoring and evaluating performance.

What is Bend-Tech software?

+Bend-Tech software is a suite of applications designed to support various aspects of the manufacturing process.

What are the benefits of using Bend-Tech software?

+The benefits of using Bend-Tech software include improved efficiency, enhanced product quality, reduced costs, and increased transparency.

How is Bend-Tech software implemented?

+Bend-Tech software can be implemented and integrated with existing systems and processes. The implementation process typically involves a needs assessment, software configuration, training and support, and ongoing maintenance and support.