Blast Tech sandblasting is a versatile and effective method for enhancing surfaces in various industries, including construction, manufacturing, and art. This technique involves propelling abrasive materials, such as sand or other minerals, at high velocity onto a surface to remove imperfections, smooth out rough edges, and create a desired texture. In this article, we will explore five ways Blast Tech sandblasting enhances surfaces, making it an essential process in many applications.

Sandblasting is a widely used technique for surface preparation, and its benefits are numerous. By removing dirt, grime, and other contaminants, sandblasting creates a clean surface that is ideal for painting, coating, or other treatments. Moreover, sandblasting can help to reduce the risk of accidents by removing slippery substances and creating a textured surface that provides better traction. Whether you're a contractor, manufacturer, or artist, sandblasting can help you achieve the desired surface quality for your project.

In various industries, sandblasting is used to prepare surfaces for different applications. For instance, in the construction industry, sandblasting is used to clean concrete surfaces before applying a new layer of paint or coating. In the manufacturing industry, sandblasting is used to remove rust and corrosion from metal surfaces, making them suitable for welding or other processes. In the art world, sandblasting is used to create intricate designs and patterns on glass, stone, and other materials. Regardless of the industry, sandblasting is an essential process that enhances surfaces in many ways.

h2>Removing Imperfections and Contaminants

One of the primary ways Blast Tech sandblasting enhances surfaces is by removing imperfections and contaminants. Sandblasting can effectively remove dirt, grime, rust, and other substances that can compromise the quality of a surface. By propelling abrasive materials at high velocity, sandblasting can dislodge even the most stubborn contaminants, leaving the surface clean and smooth. This process is particularly useful in industries where surface quality is critical, such as aerospace, automotive, and construction.

For example, in the aerospace industry, sandblasting is used to remove corrosion and other contaminants from metal surfaces, ensuring that the surface is smooth and even. This process is critical in maintaining the structural integrity of aircraft and other vehicles. Similarly, in the construction industry, sandblasting is used to remove dirt and grime from concrete surfaces, creating a clean surface for painting or coating.

h2>Smoothing Out Rough Edges

Another way Blast Tech sandblasting enhances surfaces is by smoothing out rough edges. Sandblasting can effectively remove sharp edges and burrs from metal surfaces, creating a smooth and even finish. This process is particularly useful in industries where precision is critical, such as manufacturing and engineering. By smoothing out rough edges, sandblasting can help to reduce the risk of accidents and improve the overall quality of a surface.

For instance, in the manufacturing industry, sandblasting is used to remove burrs and sharp edges from metal parts, creating a smooth surface for assembly or other processes. This process is critical in maintaining the quality of manufactured goods and ensuring that they meet precise specifications.

h2>Creating a Desired Texture

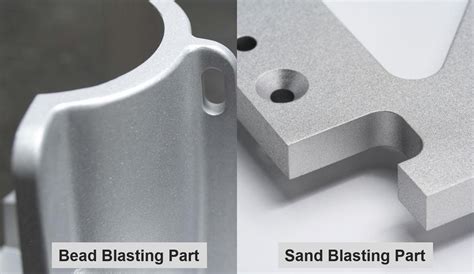

Blast Tech sandblasting can also be used to create a desired texture on a surface. By adjusting the abrasive material and blasting pressure, sandblasting can create a range of textures, from smooth and even to rough and irregular. This process is particularly useful in industries where texture is critical, such as art and architecture. By creating a desired texture, sandblasting can add visual interest and depth to a surface.

For example, in the art world, sandblasting is used to create intricate designs and patterns on glass, stone, and other materials. By adjusting the abrasive material and blasting pressure, artists can create a range of textures, from smooth and even to rough and irregular. This process allows artists to add visual interest and depth to their work.

h2>Preparing Surfaces for Painting or Coating

Blast Tech sandblasting can also be used to prepare surfaces for painting or coating. By removing dirt, grime, and other contaminants, sandblasting creates a clean surface that is ideal for painting or coating. This process is particularly useful in industries where surface quality is critical, such as construction and manufacturing. By preparing surfaces for painting or coating, sandblasting can help to ensure that the surface adheres well to the paint or coating, creating a strong and durable bond.

For instance, in the construction industry, sandblasting is used to prepare concrete surfaces for painting or coating. By removing dirt and grime, sandblasting creates a clean surface that is ideal for painting or coating. This process helps to ensure that the surface adheres well to the paint or coating, creating a strong and durable bond.

h2>Reducing the Risk of Accidents

Finally, Blast Tech sandblasting can help to reduce the risk of accidents by removing slippery substances and creating a textured surface that provides better traction. This process is particularly useful in industries where safety is critical, such as construction and manufacturing. By reducing the risk of accidents, sandblasting can help to create a safer working environment and reduce the risk of injury or damage.

For example, in the construction industry, sandblasting is used to remove slippery substances from concrete surfaces, creating a textured surface that provides better traction. This process helps to reduce the risk of accidents and create a safer working environment.

In conclusion, Blast Tech sandblasting is a versatile and effective method for enhancing surfaces in various industries. By removing imperfections and contaminants, smoothing out rough edges, creating a desired texture, preparing surfaces for painting or coating, and reducing the risk of accidents, sandblasting can help to achieve the desired surface quality for a project. Whether you're a contractor, manufacturer, or artist, sandblasting can help you achieve the desired surface quality for your project.

Gallery of Sandblasting

FAQ

What is sandblasting?

+Sandblasting is a surface treatment process that uses compressed air to propel abrasive materials onto a surface, removing dirt, grime, and other contaminants.

What are the benefits of sandblasting?

+The benefits of sandblasting include removing imperfections and contaminants, smoothing out rough edges, creating a desired texture, preparing surfaces for painting or coating, and reducing the risk of accidents.

What are the common applications of sandblasting?

+Sandblasting is commonly used in various industries, including construction, manufacturing, and art, to prepare surfaces for painting or coating, remove rust and corrosion, and create intricate designs and patterns.