The importance of proper chimney pipe installation cannot be overstated, especially when it comes to wood-burning stoves, fireplaces, and other fuel-fired appliances. A well-installed chimney pipe is crucial for ensuring safe and efficient operation, while also protecting against potential hazards such as carbon monoxide poisoning, chimney fires, and structural damage. In this article, we will delve into the world of Dura Tech chimney pipe installation and safety, providing a comprehensive guide for homeowners, contractors, and industry professionals.

Understanding Dura Tech Chimney Pipes

Dura Tech chimney pipes are a popular choice among homeowners and contractors due to their durability, versatility, and ease of installation. These pipes are designed to withstand the harsh conditions of combustion byproducts, including high temperatures, corrosive gases, and moisture. Dura Tech chimney pipes are constructed from heavy-gauge steel, stainless steel, or aluminum, making them resistant to rust, corrosion, and damage from extreme weather conditions.

Benefits of Dura Tech Chimney Pipes

Dura Tech chimney pipes offer several benefits, including:

- Durability: Dura Tech chimney pipes are built to last, with a lifespan of up to 20 years or more, depending on the material and installation quality.

- Versatility: Dura Tech chimney pipes can be used with a variety of fuel-fired appliances, including wood-burning stoves, fireplaces, and pellet stoves.

- Ease of installation: Dura Tech chimney pipes are designed for easy installation, with a simple, push-fit connection system that eliminates the need for specialized tools or expertise.

- Cost-effectiveness: Dura Tech chimney pipes are a cost-effective solution for homeowners and contractors, offering a competitive price point without compromising on quality or performance.

Pre-Installation Considerations

Before installing a Dura Tech chimney pipe, it's essential to consider several factors, including:

- Appliance compatibility: Ensure that the Dura Tech chimney pipe is compatible with your fuel-fired appliance, taking into account factors such as fuel type, burning rate, and venting requirements.

- Local building codes and regulations: Familiarize yourself with local building codes and regulations, including those related to chimney installation, clearance, and maintenance.

- Roof and wall penetrations: Determine the best location for roof and wall penetrations, ensuring that they are properly sized and sealed to prevent water ingress and damage.

- Clearance requirements: Verify that the chimney pipe meets clearance requirements, including those related to combustible materials, windows, doors, and other obstructions.

Installation Steps

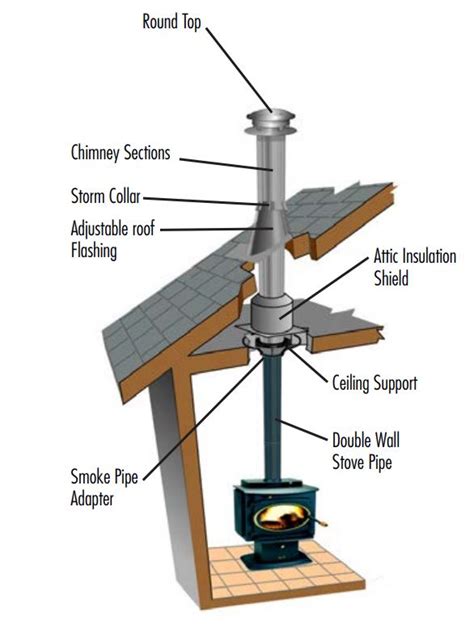

Installing a Dura Tech chimney pipe involves several steps, including:

- Planning and preparation: Plan the installation, taking into account factors such as appliance compatibility, local building codes, and roof and wall penetrations.

- Measuring and cutting: Measure and cut the chimney pipe to the required length, using a pipe cutter or saw.

- Assembly: Assemble the chimney pipe, using the push-fit connection system to connect sections.

- Installation: Install the chimney pipe, ensuring that it is properly secured to the appliance and roof or wall penetration.

- Sealing and testing: Seal the chimney pipe, using a high-temperature sealant, and test the system to ensure proper operation.

Safety Considerations

Proper chimney pipe installation and maintenance are critical for ensuring safety, as they can help prevent hazards such as carbon monoxide poisoning, chimney fires, and structural damage. Some key safety considerations include:

- Regular maintenance: Regularly inspect and maintain the chimney pipe, ensuring that it is free from damage, corrosion, and blockages.

- Clearance requirements: Ensure that the chimney pipe meets clearance requirements, including those related to combustible materials, windows, doors, and other obstructions.

- Venting requirements: Verify that the chimney pipe meets venting requirements, including those related to fuel type, burning rate, and appliance compatibility.

Troubleshooting Common Issues

Common issues with Dura Tech chimney pipes include:

- Leaks: Leaks can occur due to damage, corrosion, or improper installation. Inspect the chimney pipe regularly and seal any gaps or cracks.

- Blockages: Blockages can occur due to debris, soot, or animal nesting. Clean the chimney pipe regularly to ensure proper airflow.

- Corrosion: Corrosion can occur due to exposure to moisture, salt, or other corrosive substances. Inspect the chimney pipe regularly and apply a protective coating to prevent corrosion.

Conclusion

In conclusion, Dura Tech chimney pipe installation and safety are critical for ensuring safe and efficient operation of fuel-fired appliances. By following the guidelines outlined in this article, homeowners and contractors can ensure that their chimney pipe is properly installed, maintained, and operated, minimizing the risk of hazards and ensuring a safe and warm home.

What is the recommended clearance for a Dura Tech chimney pipe?

+The recommended clearance for a Dura Tech chimney pipe varies depending on the appliance and local building codes. However, a general rule of thumb is to maintain a minimum clearance of 6 inches from combustible materials.

How often should I inspect and maintain my Dura Tech chimney pipe?

+It is recommended to inspect and maintain your Dura Tech chimney pipe at least once a year, or more frequently if you use your appliance regularly. Regular maintenance can help prevent damage, corrosion, and blockages.

Can I install a Dura Tech chimney pipe myself?

+While it is possible to install a Dura Tech chimney pipe yourself, it is recommended to hire a professional if you are not experienced in chimney installation. Improper installation can lead to safety hazards and reduced efficiency.