Fiberglass technology has been a cornerstone of modern manufacturing for decades, offering unparalleled strength, durability, and versatility. From the automotive and aerospace industries to construction and consumer goods, fiberglass has become an indispensable material. As we continue to push the boundaries of innovation, new applications and techniques are emerging, further solidifying fiberglass's position as a vital component in various sectors.

The significance of fiberglass cannot be overstated. Its unique combination of properties, including high tensile strength, resistance to corrosion and fatigue, and low weight, makes it an ideal choice for a wide range of applications. Moreover, fiberglass is relatively inexpensive compared to other materials, making it an attractive option for industries seeking to balance performance and cost.

Fiberglass Manufacturing Process

The production of fiberglass involves several stages, from raw material selection to the final product. The most common method of fiberglass production is the continuous filament winding process, which involves the following steps:

- Raw Material Selection: Silica sand, limestone, and soda ash are the primary components used in fiberglass production.

- Melting and Forming: The raw materials are melted in a furnace at high temperatures, forming a molten glass.

- Forming and Winding: The molten glass is then formed into thin fibers, which are wound onto a spool.

- Curing: The fibers are then treated with chemicals and heat to cure and harden them.

Types of Fiberglass

There are several types of fiberglass, each with its unique properties and applications:

- E-Glass: The most common type of fiberglass, known for its high tensile strength and resistance to corrosion.

- S-Glass: A high-strength type of fiberglass, often used in aerospace and defense applications.

- C-Glass: A type of fiberglass with high chemical resistance, commonly used in chemical processing and storage.

Fiberglass Applications

Fiberglass has a wide range of applications across various industries, including:

- Automotive: Fiberglass is used in the production of car bodies, dashboards, and other components.

- Aerospace: Fiberglass is used in the manufacture of aircraft and spacecraft components, due to its high strength-to-weight ratio.

- Construction: Fiberglass is used in building insulation, roofing, and piping.

- Consumer Goods: Fiberglass is used in the production of sporting goods, such as surfboards and fishing rods.

Fiberglass Innovations

Recent advancements in fiberglass technology have led to the development of new products and applications, including:

- 3D Printing: Fiberglass is being used in 3D printing to create complex geometries and structures.

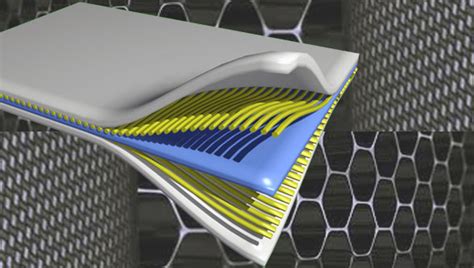

- Carbon Fiber Hybrid: A new type of fiberglass that combines the benefits of carbon fiber and fiberglass.

- Smart Fiberglass: Fiberglass with integrated sensors and monitoring systems, enabling real-time monitoring of structures.

Benefits of Fiberglass

The benefits of fiberglass are numerous, including:

- High Strength-to-Weight Ratio: Fiberglass is incredibly strong while being relatively light.

- Corrosion Resistance: Fiberglass is resistant to corrosion, making it ideal for use in harsh environments.

- Low Maintenance: Fiberglass requires minimal maintenance, reducing overall costs.

- Sustainability: Fiberglass is a relatively sustainable material, with a lower carbon footprint compared to other materials.

Fiberglass Challenges

Despite its many benefits, fiberglass also presents some challenges, including:

- Brittleness: Fiberglass can be brittle, making it prone to cracking and breaking.

- Moisture Absorption: Fiberglass can absorb moisture, leading to a loss of strength and durability.

- Recyclability: Fiberglass can be difficult to recycle, due to its complex composition.

Future of Fiberglass

As technology continues to evolve, we can expect to see new innovations and applications of fiberglass emerge. Some potential future developments include:

- Advanced Manufacturing Techniques: New manufacturing techniques, such as 3D printing, will enable the creation of complex geometries and structures.

- Smart Fiberglass: Fiberglass with integrated sensors and monitoring systems will become more prevalent.

- Sustainable Fiberglass: New sustainable materials and production methods will be developed, reducing the environmental impact of fiberglass production.

Conclusion

In conclusion, fiberglass technology has come a long way since its inception, with new innovations and applications emerging continuously. As we look to the future, it is clear that fiberglass will continue to play a vital role in various industries, from automotive and aerospace to construction and consumer goods. With its unique combination of properties, including high strength, durability, and versatility, fiberglass is an indispensable material that will continue to shape the world around us.

Gallery of Fiberglass Applications

What is fiberglass?

+Fiberglass is a type of reinforced plastic that consists of a polymer matrix reinforced with glass fibers.

What are the benefits of fiberglass?

+Fiberglass has a high strength-to-weight ratio, is corrosion-resistant, and requires minimal maintenance.

What are some common applications of fiberglass?

+Fiberglass is used in the automotive, aerospace, construction, and consumer goods industries.