A jacket tech pack is a comprehensive document that outlines the specifications, design, and manufacturing requirements for a jacket. It serves as a guide for designers, pattern makers, sample makers, and manufacturers to ensure that the final product meets the desired quality, functionality, and aesthetic standards. A well-structured tech pack is crucial for efficient communication and successful production. In this article, we will delve into the five essential components of a jacket tech pack.

Understanding the Importance of a Jacket Tech Pack

Before we dive into the components of a jacket tech pack, it's essential to understand its significance in the garment manufacturing process. A tech pack helps to:

- Ensure accurate communication between designers, manufacturers, and suppliers

- Reduce errors and misinterpretations

- Streamline the production process

- Improve quality control

- Enhance product consistency

Component 1: Design and Technical Specifications

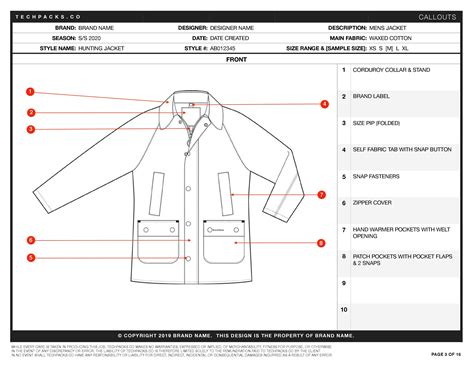

The first component of a jacket tech pack is the design and technical specifications section. This section should include:

- A clear and detailed description of the jacket design, including the style, fabric, color, and trim

- Technical specifications, such as measurements, fabric weight, and thread count

- A list of required materials, including fabrics, notions, and trims

- Any specific design features, such as pockets, zippers, or embroidery

Component 2: Measurement and Sizing Charts

The second component of a jacket tech pack is the measurement and sizing charts section. This section should include:

- A detailed measurement chart, including body measurements, sleeve length, and hem allowance

- A sizing chart, outlining the corresponding measurements for each size

- Any specific fit requirements, such as ease allowance or shaping details

Component 3: Bill of Materials (BOM)

The third component of a jacket tech pack is the Bill of Materials (BOM) section. This section should include:

- A detailed list of materials required for production, including fabrics, notions, trims, and packaging materials

- The quantity and cost of each material

- Any specific material requirements, such as certification or compliance

Component 4: Construction and Manufacturing Requirements

The fourth component of a jacket tech pack is the construction and manufacturing requirements section. This section should include:

- A detailed description of the construction process, including sewing, cutting, and finishing methods

- Any specific manufacturing requirements, such as machinery or equipment needs

- Quality control procedures and inspection points

Component 5: Labeling and Packaging Requirements

The fifth component of a jacket tech pack is the labeling and packaging requirements section. This section should include:

- A detailed description of labeling requirements, including care labels, size labels, and branding

- Packaging requirements, including bagging, boxing, or folding methods

- Any specific labeling or packaging regulations, such as compliance with laws or industry standards

Gallery of Jacket Tech Pack Examples

Frequently Asked Questions

What is a jacket tech pack?

+A jacket tech pack is a comprehensive document that outlines the specifications, design, and manufacturing requirements for a jacket.

Why is a jacket tech pack important?

+A jacket tech pack ensures accurate communication between designers, manufacturers, and suppliers, reduces errors and misinterpretations, and streamlines the production process.

What are the essential components of a jacket tech pack?

+The essential components of a jacket tech pack include design and technical specifications, measurement and sizing charts, bill of materials, construction and manufacturing requirements, and labeling and packaging requirements.

By understanding the five essential components of a jacket tech pack, designers, manufacturers, and suppliers can ensure that their products meet the highest standards of quality, functionality, and aesthetics. A well-structured tech pack is crucial for efficient communication and successful production.