In the realm of modern technology, there are numerous innovations that have transformed the way we live and work. One such innovation is PID tech, a cutting-edge solution that has revolutionized various industries. But what exactly is PID tech, and how does it work?

PID tech, or Proportional-Integral-Derivative technology, is a control loop feedback mechanism that is widely used in process control systems. It's a complex concept, but don't worry, we'll break it down in simple terms. Essentially, PID tech is a mathematical algorithm that helps control and regulate various parameters, such as temperature, pressure, flow rate, and more, in real-time.

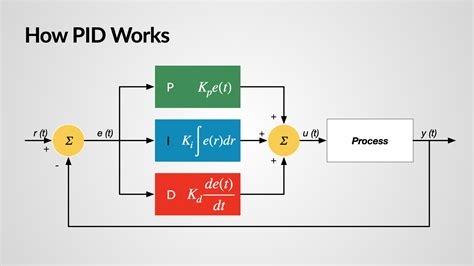

To understand how PID tech works, let's first explore its components:

- Proportional (P): This component is responsible for reducing the difference between the setpoint and the process variable. The proportional gain adjusts the output value based on the error between the setpoint and the process variable.

- Integral (I): The integral component is designed to eliminate any offset between the setpoint and the process variable. It does this by adjusting the output value based on the accumulation of past errors over time.

- Derivative (D): The derivative component predicts future errors based on the rate of change of the process variable. It helps to prevent overshooting and oscillations in the system.

Now, let's dive deeper into how PID tech works:

The PID Control Loop

The PID control loop consists of three main stages:

- Sensing: The first stage involves sensing the process variable, such as temperature or pressure, using a sensor or transmitter.

- Comparison: The sensed value is then compared to the setpoint, which is the desired value for the process variable.

- Control: The error between the setpoint and the process variable is calculated, and the PID algorithm adjusts the output value to reduce this error.

How PID Tech Regulates Parameters

PID tech regulates parameters by continuously monitoring the process variable and adjusting the output value to maintain a stable setpoint. Here's an example of how PID tech works in a temperature control system:

- Setpoint: The desired temperature setpoint is set to 100°C.

- Sensing: The temperature sensor measures the current temperature, which is 90°C.

- Comparison: The PID algorithm compares the sensed temperature (90°C) to the setpoint (100°C) and calculates the error (10°C).

- Control: The PID algorithm adjusts the heating element to increase the temperature to 100°C. The proportional component reduces the error, the integral component eliminates any offset, and the derivative component prevents overshooting.

Advantages of PID Tech

PID tech offers numerous advantages, including:

- Improved accuracy: PID tech ensures precise control of process variables, reducing errors and deviations.

- Increased efficiency: By optimizing process variables, PID tech helps reduce energy consumption and increase productivity.

- Stability: PID tech ensures stable operation, reducing oscillations and overshooting.

- Flexibility: PID tech can be applied to various industries and processes, making it a versatile solution.

Applications of PID Tech

PID tech has numerous applications across various industries, including:

- Temperature control: PID tech is widely used in temperature control systems, such as HVAC, refrigeration, and industrial processes.

- Pressure control: PID tech is used in pressure control systems, such as pumps, compressors, and valves.

- Flow control: PID tech is used in flow control systems, such as fluid processing, chemical reactions, and water treatment.

- Position control: PID tech is used in position control systems, such as robotics, CNC machines, and motion control.

Challenges and Limitations of PID Tech

While PID tech offers numerous advantages, it's not without its challenges and limitations:

- Complexity: PID tech can be complex to implement and tune, requiring expertise and experience.

- Non-linearity: PID tech assumes linear relationships between process variables, which may not always be the case.

- Disturbances: PID tech can be affected by external disturbances, such as changes in temperature or pressure.

Future of PID Tech

The future of PID tech looks promising, with advancements in artificial intelligence, machine learning, and IoT integration. These innovations will enable PID tech to:

- Improve performance: Advanced algorithms and machine learning techniques will optimize PID performance and adapt to changing process conditions.

- Increase flexibility: IoT integration will enable PID tech to communicate with other devices and systems, enhancing flexibility and scalability.

- Enhance safety: Advanced safety features and fault detection algorithms will improve the reliability and safety of PID tech.

In conclusion, PID tech is a powerful control loop feedback mechanism that has revolutionized various industries. Its ability to regulate parameters in real-time has improved accuracy, efficiency, and stability. As technology advances, PID tech will continue to play a vital role in process control systems, driving innovation and improvement.

How PID Tech Works in Real-World Applications

PID tech is widely used in various industries, including HVAC, refrigeration, industrial processes, and more. Let's explore some real-world applications of PID tech:

Temperature Control in HVAC Systems

In HVAC systems, PID tech is used to regulate temperature, humidity, and air quality. The PID algorithm monitors the temperature and adjusts the heating or cooling element to maintain a stable setpoint.

Pressure Control in Industrial Processes

In industrial processes, PID tech is used to regulate pressure, flow rate, and level. The PID algorithm monitors the pressure and adjusts the pump or valve to maintain a stable setpoint.

Flow Control in Chemical Reactions

In chemical reactions, PID tech is used to regulate flow rate, temperature, and pressure. The PID algorithm monitors the flow rate and adjusts the pump or valve to maintain a stable setpoint.

Benefits of PID Tech in Real-World Applications

The benefits of PID tech in real-world applications are numerous:

- Improved accuracy: PID tech ensures precise control of process variables, reducing errors and deviations.

- Increased efficiency: By optimizing process variables, PID tech helps reduce energy consumption and increase productivity.

- Stability: PID tech ensures stable operation, reducing oscillations and overshooting.

Conclusion

In conclusion, PID tech is a powerful control loop feedback mechanism that has revolutionized various industries. Its ability to regulate parameters in real-time has improved accuracy, efficiency, and stability. As technology advances, PID tech will continue to play a vital role in process control systems, driving innovation and improvement.

We hope this article has provided valuable insights into PID tech and its applications. If you have any questions or comments, please feel free to share them below.

What is PID tech?

+PID tech, or Proportional-Integral-Derivative technology, is a control loop feedback mechanism that is widely used in process control systems.

How does PID tech work?

+PID tech works by continuously monitoring the process variable and adjusting the output value to reduce the error between the setpoint and the process variable.

What are the benefits of PID tech?

+The benefits of PID tech include improved accuracy, increased efficiency, and stability.