The evolution of machine technology has been marked by significant advancements in recent years, with servo technology being one of the most notable innovations. Servo technology has revolutionized the way machines operate, enabling them to perform tasks with greater precision, speed, and efficiency. In this article, we will explore the five ways servo tech enhances machine performance, making it an essential component in modern machinery.

What is Servo Technology?

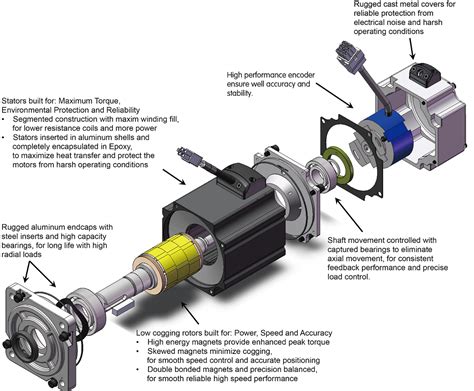

Before we dive into the benefits of servo technology, let's first define what it is. Servo technology refers to the use of servomotors, which are electric motors that use feedback mechanisms to precisely control their position, velocity, and acceleration. This allows machines to achieve precise movements and maintain consistent performance.

1. Improved Accuracy and Precision

One of the primary benefits of servo technology is its ability to provide improved accuracy and precision. Servomotors use advanced algorithms and feedback mechanisms to ensure that the machine's movements are precise and repeatable. This is particularly important in applications such as CNC machining, robotics, and medical devices, where accuracy is paramount.For instance, in CNC machining, servo technology allows for precise control of the cutting tool, enabling the creation of complex shapes and designs with high accuracy. This has led to significant improvements in product quality and reduced production times.

Key Benefits of Improved Accuracy and Precision

• Reduced error rates and improved product quality • Increased precision and repeatability • Improved production efficiency and reduced production times2. Increased Speed and Efficiency

Servo technology also enables machines to operate at higher speeds and with greater efficiency. By precisely controlling the movement of the machine, servo motors can optimize the motion profile, reducing energy consumption and increasing productivity.For example, in packaging machinery, servo technology can be used to control the movement of the conveyor belt, ensuring that products are precisely positioned and oriented for packaging. This has led to significant improvements in packaging efficiency and reduced production costs.

Key Benefits of Increased Speed and Efficiency

• Improved production efficiency and reduced production times • Reduced energy consumption and increased sustainability • Increased productivity and competitiveness3. Enhanced Safety and Reliability

Servo technology also provides enhanced safety and reliability in machine operation. By precisely controlling the movement of the machine, servo motors can detect potential safety hazards and prevent accidents.For instance, in robotic applications, servo technology can be used to control the movement of the robot's arms and grippers, ensuring that they operate safely and efficiently. This has led to significant improvements in workplace safety and reduced the risk of accidents.

Key Benefits of Enhanced Safety and Reliability

• Improved workplace safety and reduced risk of accidents • Increased machine reliability and reduced downtime • Compliance with regulatory requirements and industry standards4. Reduced Maintenance and Downtime

Servo technology also provides reduced maintenance and downtime in machine operation. By precisely controlling the movement of the machine, servo motors can reduce wear and tear on the machine's components, extending their lifespan.For example, in textile machinery, servo technology can be used to control the movement of the loom, ensuring that the fabric is precisely woven and reducing the risk of defects. This has led to significant improvements in product quality and reduced maintenance costs.

Key Benefits of Reduced Maintenance and Downtime

• Reduced maintenance costs and extended machine lifespan • Improved product quality and reduced risk of defects • Increased productivity and reduced downtime5. Improved Adaptability and Flexibility

Finally, servo technology provides improved adaptability and flexibility in machine operation. By precisely controlling the movement of the machine, servo motors can be easily programmed to perform a wide range of tasks, making them ideal for applications where flexibility is required.For instance, in 3D printing, servo technology can be used to control the movement of the print head, enabling the creation of complex shapes and designs with high precision. This has led to significant improvements in product quality and reduced production times.

Key Benefits of Improved Adaptability and Flexibility

• Improved product quality and reduced production times • Increased flexibility and adaptability in machine operation • Reduced costs and improved competitiveness

In conclusion, servo technology has revolutionized the way machines operate, enabling them to perform tasks with greater precision, speed, and efficiency. With its ability to provide improved accuracy and precision, increased speed and efficiency, enhanced safety and reliability, reduced maintenance and downtime, and improved adaptability and flexibility, servo technology is an essential component in modern machinery. As technology continues to evolve, it's likely that servo technology will play an increasingly important role in shaping the future of machine operation.

What is servo technology?

+Servo technology refers to the use of servomotors, which are electric motors that use feedback mechanisms to precisely control their position, velocity, and acceleration.

What are the benefits of servo technology?

+The benefits of servo technology include improved accuracy and precision, increased speed and efficiency, enhanced safety and reliability, reduced maintenance and downtime, and improved adaptability and flexibility.

What are some common applications of servo technology?

+Some common applications of servo technology include CNC machining, robotics, medical devices, packaging machinery, textile machinery, and 3D printing.

Share your thoughts on servo technology and its applications in the comments section below!