The importance of solids control in the drilling industry cannot be overstated. As the demand for oil and gas continues to rise, drilling operations are becoming increasingly complex, with deeper wells and more challenging environments. Solids control technology plays a critical role in ensuring efficient and effective drilling, while also reducing costs and environmental impact.

In recent years, the development of advanced solids control systems has revolutionized the drilling industry. These systems enable drillers to effectively manage drilling fluids, remove solids and contaminants, and optimize drilling performance. By doing so, solids control technology helps to reduce the risk of drilling-related problems, such as stuck pipes, wellbore instability, and lost circulation.

As the drilling industry continues to evolve, the need for efficient and effective solids control solutions has never been more pressing. With the increasing complexity of drilling operations and the growing emphasis on environmental sustainability, drillers are looking for innovative solutions that can help them to optimize their operations while minimizing their impact on the environment. Solids control technology is at the forefront of this effort, providing drillers with the tools they need to achieve their goals.

What is Solids Control?

Solids control is the process of managing drilling fluids and removing solids and contaminants from the drilling system. This is typically achieved through the use of specialized equipment, such as shakers, centrifuges, and hydrocyclones, which work together to separate and remove solids from the drilling fluid. The goal of solids control is to maintain a stable and consistent drilling fluid, which is essential for efficient and effective drilling.

Components of a Solids Control System

A typical solids control system consists of several key components, including:

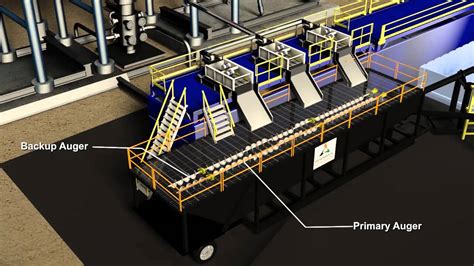

- Shale shakers: These are the primary solids removal devices, which use a vibrating screen to separate solids from the drilling fluid.

- Desanders: These are centrifugal devices that use a spinning motion to remove larger solids from the drilling fluid.

- Desilters: These are also centrifugal devices, but they use a smaller cone size to remove smaller solids from the drilling fluid.

- Centrifuges: These are high-speed centrifuges that use a spinning motion to remove ultra-fine solids from the drilling fluid.

- Hydrocyclones: These are conical-shaped devices that use a spinning motion to remove solids from the drilling fluid.

Benefits of Solids Control

Solids control technology offers a range of benefits to drillers, including:

- Improved drilling efficiency: By removing solids and contaminants from the drilling fluid, solids control technology helps to maintain a stable and consistent drilling fluid, which is essential for efficient and effective drilling.

- Reduced drilling costs: Solids control technology can help to reduce drilling costs by minimizing the amount of drilling fluid required, reducing the need for drilling fluid additives, and extending the life of drilling equipment.

- Environmental sustainability: Solids control technology helps to minimize the environmental impact of drilling operations by reducing the amount of drilling fluid waste and preventing contamination of the surrounding environment.

- Enhanced safety: Solids control technology helps to reduce the risk of drilling-related accidents and injuries by removing hazards such as stuck pipes and wellbore instability.

Real-World Applications of Solids Control

Solids control technology is used in a wide range of drilling applications, including:

- Oil and gas drilling: Solids control technology is critical in oil and gas drilling, where it is used to manage drilling fluids and remove solids and contaminants from the drilling system.

- Geothermal drilling: Solids control technology is used in geothermal drilling to manage drilling fluids and remove solids and contaminants from the drilling system.

- Mining drilling: Solids control technology is used in mining drilling to manage drilling fluids and remove solids and contaminants from the drilling system.

Future of Solids Control

As the drilling industry continues to evolve, the need for efficient and effective solids control solutions will only continue to grow. In the future, we can expect to see even more advanced solids control technologies, such as:

- Automated solids control systems: These systems use advanced sensors and algorithms to automatically adjust solids control parameters and optimize drilling performance.

- High-speed centrifuges: These centrifuges use advanced rotor designs and high-speed motors to remove ultra-fine solids from the drilling fluid.

- Advanced hydrocyclones: These hydrocyclones use advanced cone designs and materials to remove solids from the drilling fluid.

Challenges and Opportunities

While solids control technology has come a long way in recent years, there are still several challenges and opportunities for further innovation and improvement. Some of the key challenges and opportunities include:

- Developing more efficient and effective solids control systems: This could involve the development of new technologies, such as advanced centrifuges and hydrocyclones, or the improvement of existing technologies.

- Reducing the environmental impact of drilling operations: This could involve the development of more sustainable drilling fluids and the reduction of drilling fluid waste.

- Improving drilling safety: This could involve the development of more advanced sensors and monitoring systems to detect and prevent drilling-related hazards.

We hope this article has provided you with a comprehensive overview of solids control technology and its importance in the drilling industry. If you have any questions or comments, please don't hesitate to reach out. We'd love to hear from you!

What is solids control?

+Solids control is the process of managing drilling fluids and removing solids and contaminants from the drilling system.

What are the benefits of solids control?

+The benefits of solids control include improved drilling efficiency, reduced drilling costs, environmental sustainability, and enhanced safety.

What are the future trends in solids control technology?

+The future trends in solids control technology include the development of automated solids control systems, high-speed centrifuges, and advanced hydrocyclones.